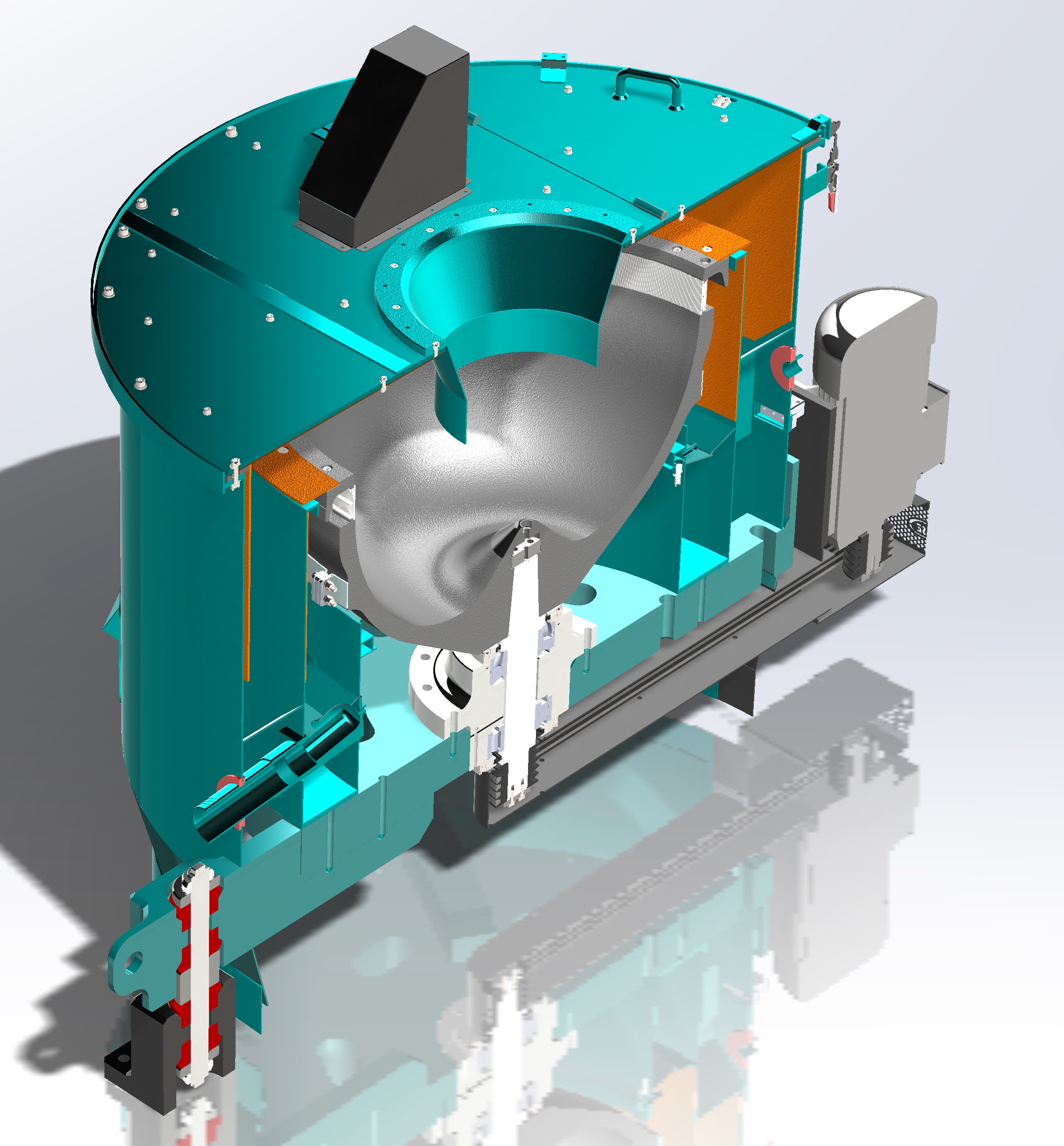

Continuous de-oiling machine aimed at the centrifugation of ferrous and non-ferrous chips, continuous feeding from the top of the machine, channelled extraction of the oil or emulsion.

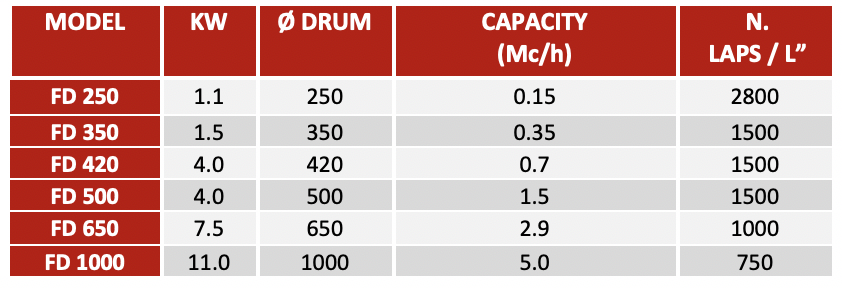

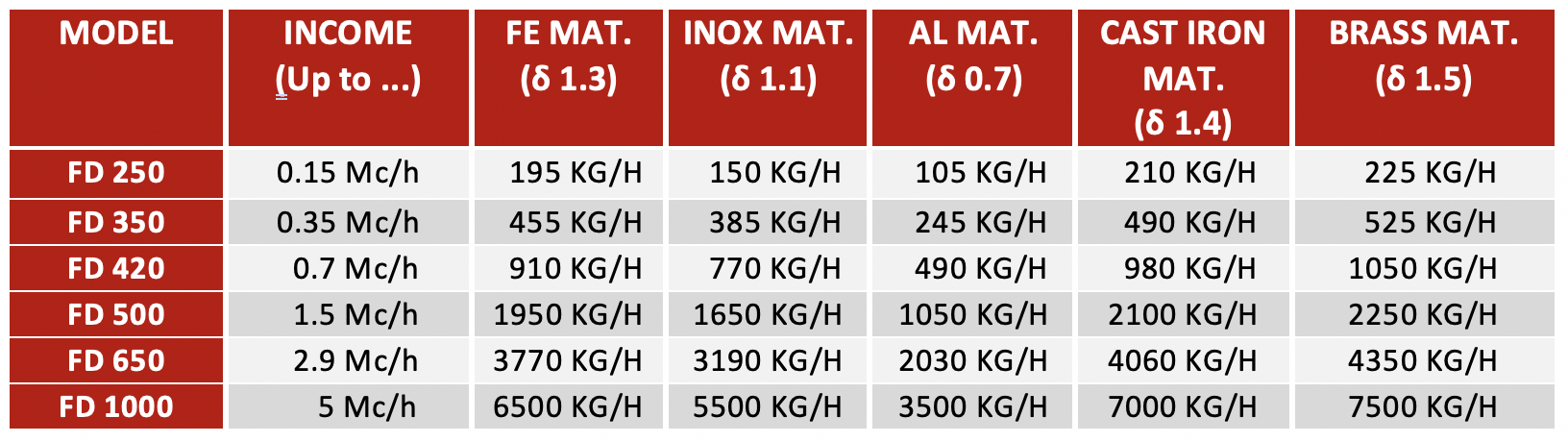

Centrifuges of small size suitable as an integration of the most performing machineries, with production capacity of over 7,000 KG/H.

High performing machineries capable of recovering the coolant to obtain less than 2% of residual moisture for a significant economic return.

Basic version:

- Support frame with a resistant carpentry, removable doors for easy access (cleaning and checking).

- Specific parts in contact with the chips are covered by wear-resistant materials.

- Hardened steel drum made through CNC manufacturing.

- Internal vibration dampers to reduce vibrations.

- Particular shape of the filter that optimizes the final result.

- Control and stop system activated in case of excessive vibration.

Accesorizes:

- Electric control panel.

- Support frame to place the centrifuge on top of a conveyor.

- Coolant recovery tank with level control and washing pump